The action of grinding is essentially performed to finish a part to size. The work is demanding and exacting. There are different types of grinding methods. There is also various equipment, including those operated using CNC technology involved. One of the most popular or at least common types of grinding is OD Grinding.

What Is OD Grinding?

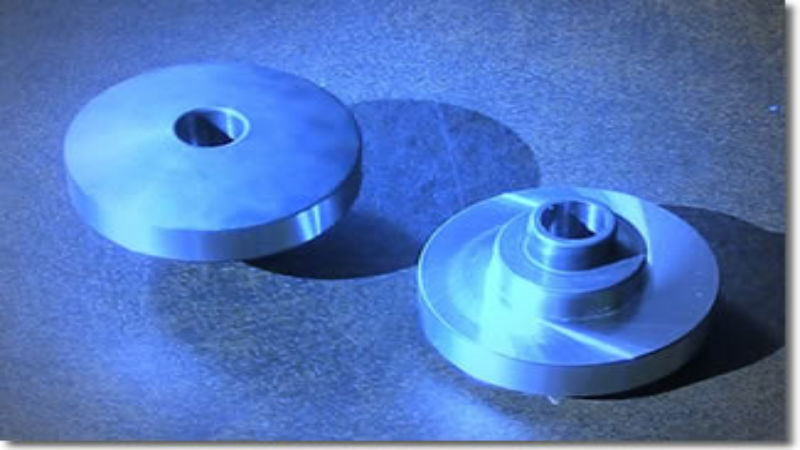

Of all the common forms of grinding, OD grinding is the most conventional. Highly in demand, OD or outer dimension grinding is precision grinding. It involves, as is the case with all forms of grinding, reducing the surface – in this case the outer surface, of the material of a component to an exact size and shape.

Types of OD Grinding

OD grinding is a form of grinding that has, over the years and with advances in technology, is divided in accordance with the technique employed to mount the workplace and the main direction of the feed. As a result, types of this form of grinding are considered in the below categories:

* OD peripheral-transverse grinding or plunge grinding

* OD peripheral-longitudinal grinding or feed grinding

* Centerless grinding: This OD grinding process has no mechanical devices constraining the workpiece, hence the name “centerless”. It has two divisions:

* OD centerless peripheral-transverse grinding

* OD centerless peripheral-longitudinal grinding

The choice of equipment will depend upon the usual variants. This includes the intended purpose of the part and client, legislated or other organizational specifications.

Industrial Application of OD Grinding

Manufacturers are dependent upon OD grinding. Many industries require the process before they can complete their products. Axle shafts, bearings, mandrels and camshafts are but a few examples of products that require this type of grinding. Industrial applications are prominent, popular and essential in the following manufacturing concerns:

* Automotive industry e.g. camshafts, crankshafts

* Aircraft

* Bearing manufacturing Engine manufacturing

* Metalworking and Machine Shop Industries

* Shipbuilding

* Tool Rooms

* Turbine manufacturing

The ability to produce smooth and exacting surfaces continues to make OD grinding popular among a wide variety of industrial concerns.

OD Grinding

In grinding, you have two major types of grinding. These are OD and ID. Each addresses the specific area requiring reduction through the process of grinding away the excessive and undesirable material. This may be metal. It may also be composite or plastic. While ID grinding addresses the interior of a component, it is the responsibility of OD grinding to remove all extraneous material from the exterior to produce the ideal for its industrial application.